Show:

The Impact of Equipment Maintenance Software on Business Sustainability

Maintenance is the huge wheel for equipment-driven businesses that keep operations on track. From a broader perspective, equipment maintenance significantly impacts overall earnings, reputation, and durability.

You increase equipment life cycles, minimize risk and costs, and boost customer satisfaction. Periodic, preventative, and ad hoc equipment maintenance is very important. The benefits extend beyond solid business margins. Companies are discovering that best-in-class maintenance methods naturally integrate into sustainable models. In particular, businesses that deal with rental equipment, leasing, and services.

‘Sustainable’ has become a catchphrase for working methods with low environmental effects. It is, of course, more complicated than that, including several ecological, economical, and social factors. What’s intriguing about sustainable models is that they mix profit and knowledge with reasonable ease. As a result, strategic equipment maintenance as part of asset management has the same objective. Ensure that the equipment’s functioning is assured and that care is completed on time always. Even if your goal is to maximize the use of your equipment, when you combine commercial acumen with technological advancements, the rewards naturally match with sustainability.

What is equipment management software?

Equipment management software allows you to plan, monitor, and track the health and performance of your equipment—use the software to keep your manufacturing lines functioning to meet production needs.

How does equipment management software help

Manufacturers use equipment management software to increase equipment dependability, task completion rates, repair parts turnover, etc. Fleetio’s equipment management software‘s tracking capabilities make it simple to plan, schedule, and prioritize vital maintenance.

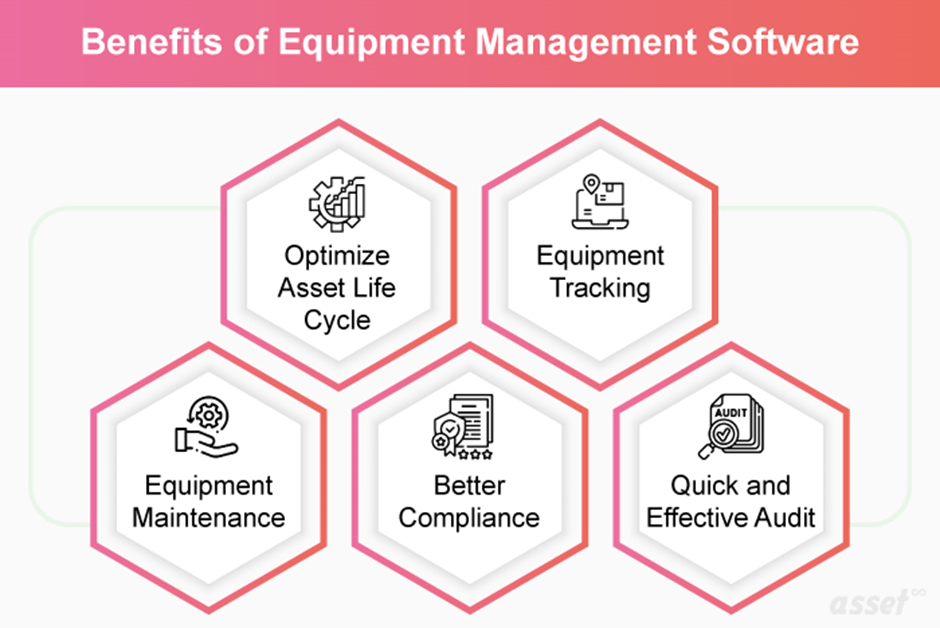

What are the advantages of using equipment management software

Equipment management software allows you to track the health of your equipment in real-time throughout your whole business. Tracking and monitoring your assets allows you and your team to increase productivity, streamline procedures, and keep your equipment running better for longer.

Equipment maintenance software is rewarding in the following manner:

1. Environmental benefits

The benefits include longer operating life cycles, less actual waste, and fewer requirements for virgin equipment and spare components. It also implies improved fuel and emissions control and a smaller footprint for transportation and storage.

2. Social benefits

The key advantages are customer and staff happiness and safety. Furthermore, it increased opportunities for cooperation and collaboration with commercial and public organizations. Finally, enhanced compliance and transparency, as well as a strong reputation and brand confidence in local and worldwide communities.

3. Economic benefits

There is a decreased expense for resources and equipment and the chance to achieve more with what you have today and make intelligent growth investors rely on a big picture vision that benefits your organization and the more significant marketplace.

You feel tremendous pressure to succeed due to narrow margins, fickle consumers, many rules, and numerous stakeholders across multiple locations. Many firms are drawn to the fact that they can do well for themselves. Furthermore, they include business sustainability in their success narrative.

Equipment maintenance software aids in the prediction of equipment problems. Consequently, teams in industries ranging from industrial maintenance to oil and gas maintain production equipment running efficiently.

Asset management with a user-friendly interface and mobile software access, technicians and line operators embrace the benefits of equipment maintenance software and rapidly learn how to see and execute assigned work orders and submit work requests. Managers receive access to crucial data for making educated decisions, such as critical asset downtime, downtime, overdue PMs, failures, inventory management, emergency work, and other maintenance KPIs. Additionally, equipment maintenance software aids in regulatory and ISO compliance. It is time you started utilizing this sort of equipment maintenance software.

- Increase the completion rate of work orders and requests by controlling them from any browser-based device.

- Reduce waste and spoilage by tracking the availability of spare parts and linking them with assets and PMs.

- Utilize maintenance resources more efficiently by seeing work schedules in the calendar view by day, week, or month.

- Increase asset dependability and uptime by creating calendar- and meter-based PM activities for each asset.

- Avoid unforeseen breakdowns by scheduling work as needed based on condition monitoring data.

- Access equipment information quickly by saving asset nameplate data, specifications, location, component hierarchy, and more.

How technology enables you to transform asset management into lucrative long-term sustainability

The main point is that technology is the key to profitable, long-term asset management. As a result, equipment maintenance provides several good possibilities. Take, for example, service orders and guarantee/claim work orders that are produced, monitored, and followed up on. To operate successfully with a particular vendor and customer needs, you’ll need the following:

1. All your equipment’s information is in one location

ISV solutions for equipment-driven businesses provide pre-built connectivity with your central ERP system. As a result, your solution should make it simple to collect and arrange equipment data from various entry points. Internal front and back offices, interactions with third-party organizations, mobile apps, and IoT sensors are all examples. Along with consolidated data, ensure that your solution allows you to swiftly create customer and vendor-specific information. And accessed by internal and external users. Information views should be role-specific and automatically updated so that data is always up to date.

2. Tools for tracking maintenance requirements

Sustainability models are intended to strengthen your strategic muscles. This is reflected in computerized monitoring and management systems. For example, IoT sensors continually monitor everything from oil levels to weather conditions and relay that data to planning dashboards. Planners use dashboard tools to track KPIs for equipment and parts. They should be able to work proactively to establish if regular maintenance is genuinely required and forecast future problems far in advance. Service technicians also use mobile devices to collect and transmit information to planners.

3. Management of resources, replacement parts, and logistics of equipment

Planners demand all-in-one views of the state of equipment filtered for customer/vendor requirements. They are linked with resources with the necessary skills, qualifications, and availability. They should be able to collaborate in real-time with suppliers, third-party transportation, depots, and warehouses and always have the most up-to-date information at their fingertips. Scheduling and rescheduling is as easy as dragging and dropping, allowing for flexible change management.

4. Action management drives all-in-one service orders

On mobile devices, resources should be able to receive maintenance orders with step-by-step activities and all customer-ready paperwork. Your central system is updated as tasks are done. Resources immediately receive customer signoffs and approval, with complete documentation sent to clients, vendors, suppliers, and your back office.

Organizations use equipment maintenance software to gain control of their maintenance processes and boost efficiency. Companies reduce their environmental footprint by automating jobs, removing extra paperwork, and simplifying critical procedures. Continue reading to find out how equipment maintenance software improves sustainability.

5. Change from a reactive to a proactive maintenance approach

Upkeep of equipment maintenance personnel can automate the scheduling of inspections and routine maintenance chores using software such as Enterprise Asset Management (EAM) solutions. Companies assist in maintaining assets working smoothly and avoid costly, unneeded repairs by doing so.

Many firms’ major sustainability programs aim to prevent expensive reactive maintenance practices, such as disregarding an asset until it breaks and repairs are required. They assist companies in implementing more proactive maintenance strategies, which focus on preventing problems before they occur. Preventive maintenance extends the life of assets while lowering expenses.

6. Consider going paperless

To prevent piles of paper around their houses, you or someone you know probably receive their utility and credit card bills virtually entirely online. The same holds in the workplace, and maintenance operations are no exception. Numerous work orders, equipment manufacturer’s manuals, past work histories, vendor contact information—the list goes on and on.

Fortunately, equipment maintenance software improves office sustainability by reducing the need for printed copies. Maintenance personnel readily get essential information about work orders on their desktops or even on the road using mobile equipment maintenance software apps. Carrying clipboards, locating files, and delving through filing cabinets will soon become obsolete.

7. Avoid stockpiling spare parts and making unnecessary deliveries

Many businesses have inventory storerooms supporting maintenance, repair, and operations (MRO) programs. However, if the department is organized, it might be easier for maintenance employees to identify the parts needed for repairs. Successfully deploying equipment maintenance software allows workers to locate the specific location of spare parts, so it’s no longer essential to trawl through warehouses to discover what you need.

Furthermore, configure automated component reordering to guarantee that you always have the replacement parts you require the most. For example, you may configure the software to automatically reorder a specified amount of a domain when the inventory level falls below a given threshold. This ensures that maintenance personnel only order the required components, allowing them to avoid stockpiling unnecessary parts. This minimizes needless delivery, lowering your carbon impact.

8. Comply with environmental regulations

Regulatory criteria, including environmental rules, must be met by industries across the board. For example, the EPA uses various strategies to assist in safeguarding the environment, and one of its most important instruments is the creation of laws. Equipment maintenance software simplifies compliance with regulatory requirements by keeping thorough records required to establish compliance.

Produce reports outlining maintenance conducted on any single piece of equipment over some time. Audits and random inspections are no longer cause for concern—with equipment maintenance software for compliance, they’re a piece of cake.

9. Equipment maintenance software improves sustainability while reducing costs

Companies that utilize equipment maintenance software run more sustainably and save much money. Other benefits of equipment maintenance systems include reduced downtime, reduced employee overtime, increased safety, increased productivity, and more. One of the most significant advantages is the capacity to make better decisions that influence your organization’s long-term goals.

So what is the impact of using equipment maintenance software on your business’s sustainability?

The result is efficient, timely, and paperless maintenance that maximizes asset management’s economic, social, and environmental elements. Look for technology already in touch with sustainability while looking for advances in equipment usage and profitability.

About the author:

Fatema Zariwala is a writer and editor based in Mumbai, India. She has 7 years of experience writing blogs and articles. She likes to read non-fiction and play board games with her kids during her free time.

Return to Previous Page

Return to Previous Page