Show:

The Past, Present, And Future Of Engineering Simulation

Industrial engineering has always been complex.

With so many elements going into making one successful product, human errors and miscalculations are inevitable. This makes testing and reiteration two critical processes here.

Simulation engineering is thus an indispensable part of the process. Having questions about its history, recent trends and future potential is thus natural for any industrial engineer.

To answer in one sentence, simulation engineering has undergone massive transformation and it continues to do so in the future.

Bet it in terms of approach, methodologies, or tools, designer’s lives will be disrupted with new waves of improvement. This makes having a flexible and adaptive mindset is what will keep you prepared for the future. Interested to know how to do so?

In this blog post, we take a deep dive into the past, present, and future of engineering simulation to better assess it and adapt to its landscape.

Engineering simulation: the past, present, and future

To understand the complete scope of simulation engineering, it is critical to understand why it all started. This will give you a solid anchor to the possibilities of the future.

The best part?

Disrupting the landscape for faster, easier and efficient processes and tools would be more accessible. More importantly, what looked completely impossible to achieve would be finally possible to achieve. That too, with ease. Designers can declutter their space from unproductive work and get more creative energy.

Going through its timeline basically creates a win-win situation for all industrial engineers. They can gauge the vulnerabilities, limitations, and opportunities of the space. Let’s dive in.

The challenges of the past

Traditional industrial engineering was innately complex and limited in its approach.

Engineers could not create functioning design models without investing time to develop the final product. This means all the products were a one-shot process. The only means of simulation or visualization was a 2D version of the designs on paper. The only tools that a designer had back then were a protractor and compass leaving limited room for experiments. Also, due to this pen and paper involvement, the design versions were just a handful.

Naturally, the occurrence of the high frequency of faults and vulnerabilities was inevitable. As a consequence of these loopholes or miscalculations, the complete design process could suffer a major setback only delaying the final product development.

More so, the results could be catastrophic not only in terms of monetary loss but human lives. To better understand, consider a bridge in making during the 1800s. Building a bridge with glitches could become a major life-threatening event.

The birth of simulation software

The critical need to create a workspace of more confident product development in the industrial engineering industry is what gave birth to simulation software.

Over the past few decades, the simulation software market has seen nothing but unchecked growth. The obvious benefits, ease, and opportunities that the software brings to industrial engineers could not be overlooked. Moreso, its benefits were not restricted to only better products. It benefitted business in terms of revenue. From improvement in time, development costs, the longevity of the product, space design, human resources, it could optimize all. But if there is one software that pioneered the industrial design industry it is CAD.

Infact, Cambasi has been delivering insights into the 2D and 3D CAE (computer-aided engineering) market since 2015.

The traditional model of engineering simulation rendered multiple benefits. From failure analysis, design drivers, systems engineering, there are multiple areas of the design process that modern technology alleviated successfully.

The present conditions

Simulation software has helped to foster customer-driven innovation to reduce time and cost investment of product development for almost half a century now.

In modern times, the technological revolution has significantly contributed to moving the needle of the industry forward. From aircraft, trains, heavy machinery to electronics almost every industrial vertical has benefitted. Infact, the sheet number of SaaS products available today in the market is a testament to its disruption. Tools like nTopology, Altair, and MATLAB are to name a few. But that is not all.

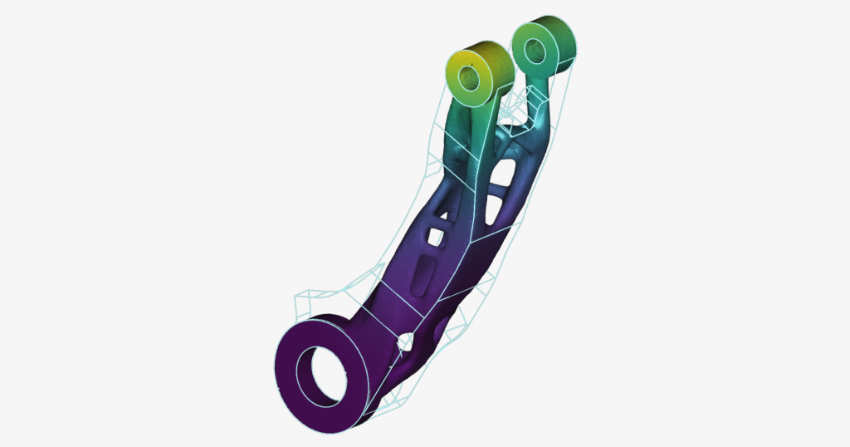

Combining the power of cloud computing and AI, simulation software has ear-marked the dawn of a new era. What traditional simulation software failed to achieve, the power of generative technology could do in a fraction of seconds. You can now achieve all possible designs irrespective of complexity in a fraction of time. You don’t even need to embed a team of designers to do it. What’s more?

Now, you can plan and execute the complete design process from end to end. From ideation to final launch along with reiteration, everything is possible. But the journey of simulation software has not reached its peak yet.

On the contrary, the software fueled by generative design we see today is the first generation of future software. There is so much more we can achieve.

What does the future behold?

The future of simulation engineering certainly lies in the powerful technology of generative design, which is still in its early stages of development.

Integrating the power of cloud computing and machine learning is redefining the future of how industrial engineers approach design development.

Not only is it capable of lightspeed production but brings superior quality to the process. Shapes and designs that were traditionally impossible to think of tending to be quite easily achievable in the future.

The best part? Because of the least intervention of humans in the design process, you end up saving in terms of your workforce too.

Rooting to this quality, there are a few trend shifts that you can expect to see in the near future.

The major shifts of the future of engineering simulation

1. Microservices for simulation

In addition to ‘simulation microservices’, there are high chances to witness the progress made in the use of ‘microservices for simulation’.

Here, you can transform the major parts of simulation like geometry to finally undertake to mesh. The simulation process now has multiple services like geometry services, meshing services, solver services, and more. Instead of one single process, there will be geometry, meshing, and solver services, broken into smaller nodes with specific tasks to accomplish. Thus the microservice comes into existence.

Moreover, this shift towards microservices architecture is also evident in various other fields beyond simulation. For instance, software developers are increasingly adopting this approach to create scalable and efficient applications. The strangler pattern, which involves gradually replacing parts of an existing system with new microservices, is gaining popularity as a strategy to modernize and enhance complex software systems while minimizing disruption. This means that the concept of microservices is not limited to simulation alone; it’s a versatile approach that can revolutionize various industries by improving flexibility, scalability, and overall system performance.

2. Digital adoption

The future of engineering simulation is going to be digital.

There are high chances to see the adoption of AI technologies like virtual reality and augmented reality to simulate the physical world. Currently, digital twins are booming and will continue to be so.

Here, engineers are digitizing information about a physical component of a machine, enabling them to analyze performance and monitor systems to head off problems with the real-world component or machine before they occur.

What follows is the minimization of costs, both downtime and associated, and a fast-paced technology adoption due to obvious benefits.

3. Predictive design development

Perhaps the greatest challenge for today’s product developers is the need to continuously innovate. The growing need for modern customers has made the need for the next big change inevitable. They need effective yet cost-efficient products all at record speed.

This is where predictive design comes into play. Using the capabilities of machine learning, developing complex yet viable product designs is a matter of minutes now.

The best part is the quality and precision of the designs tend to grow to be better with time. The machine learning model so installed continues to learn from every iteration you undergo here.

4. Multiphysics interaction

One of the biggest transformations that the engineering simulation industry is predicted to witness is in its approach to problem analysis.

The agile methodology will take over the step-by-step, waterfall approach. This would be successfully done with the integration of multiphysics.

Although a technology dating back to an origin of 50 years, it has never been thought of to put to rigorous use until now. But to understand why this technology suddenly piqued the interests of the specialists in the field, you would need to understand the flaws of the traditional method.

The traditional method was effective yet immensely limited in its capabilities when it came to fast product development. With today’s consumer’s growing demands and decreasing attention span, the traditional method fails to meet expectations.

This is exactly where the agile, multiphysics method comes in. This multidisciplinary analysis and optimization process reduces the time required for testing, reiterating, and launching the final product.

As a result, there is a significant improvement in product development to market launch time, developmental costs, and product performance.

Conclusion

The world of technology is continuously evolving. What today is cutting-edge is the new normal to tomorrow. This means if you have to sustain yourself in the landscape, becoming proficient in today’s technology is not sufficient.

You need to start preparing for the future.

Keep a learner’s mindset.

Understanding the complete journey of engineering simulation would certainly give you a better insight to predict the future. But, be open to the possibility of disruption and stay curious. It will give you sustenance.

So now when you have a thorough understanding of engineering simulation, there is just one question left to answer. Are you going to wait for the disruption or be one?

About the author:

Atreyee Chowdhury works full-time as an Instructional Designer and is passionate about writing. She has helped many small and medium-scale businesses achieve their content marketing goals with her carefully crafted and compelling content. She lives in Bangalore, India with her husband and parents. She loves to read, experiment with different cuisines, travel, and explore the latest content marketing and L&D trends in her free time. You can reach her on Linkedin or write to her at atreyee.c@gmail.com for any content writing/marketing requirements.

Return to Previous Page

Return to Previous Page